Ramping Up: Lockheed Martin Steadily Increasing Production of High-Demand Systems

The demand for 21st Century Security solutions is at an all-time high, as the U.S. military and its allies turn to proven capabilities to deter and defend against evolving threats worldwide. In response to this growing need, Lockheed Martin is prioritizing speed, agility and adaptability in its production processes, using digital transformation to ensure customers’ stay ahead of ready.

“Lockheed Martin remains committed to ramping production of high-demand systems, like HIMARS, Javelin, GMLRS, PAC-3 and more,” said Lockheed Martin Chief Operating Officer Frank St. John. “In 2024, we are on track to double HIMARS production, have increased Javelin’s production to 2,400 units per year and will deliver more than 10,000 GMLRS.

“1LMX, our digital transformation initiative that integrates cutting-edge solutions, leveraging decades of historical data, analytics, and advanced AI to augment our workforce and increase productivity levels, has propelled our ramp-up progress,” St. John continued. “We are deploying automation, robotics, and factory simulations and investing in long-lead procurement to cut missile production time, increase capacity and maintain manufacturing excellence. Through digital transformation, Lockheed Martin is not just meeting significantly increased demand at this critical geopolitical point, but leading the defense industry into the future, ensuring we continue to deliver innovative, affordable 21st Century Security solutions to our customers.”

Examples of 1LMX in action can be found at our facilities across the globe. The Javelin team, for example, has implemented new processes on the production line at the Pike County Operations facility in Troy, Alabama, that have cut missile production time by 30 minutes.

The key to keeping our customers ahead of ready, however, is Lockheed Martin’s workforce. These teams are driven by a deep sense of mission to tackle our customers’ biggest challenges and, in doing so, inspire and redefine what is possible. In May 2022, President Joe Biden visited Lockheed Martin's Troy facility to thank the workforce for their efforts and tour the Javelin production line. Last month, NATO Secretary General Jens Stoltenberg visited the Troy facility to share firsthand the critical role Lockheed Martin is playing in security and missions worldwide. “For decades, you have helped American and NATO forces maintain their technological edge,” he said as he addressed employees. “What you produce keeps people safe, and what Allies buy, helps keep American business strong.”

Accelerating Production When Seconds Count

GMLRS

Having the capability to strike from farther distances has become more crucial than ever before — that’s where GMLRS comes in. GMLRS is the primary round for the combat-proven MLRS family of launchers (HIMARS and M270). Lockheed Martin is working with the U.S. Army to increase GMLRS production capacity to 14,000 per year in 2025.

HIMARS

HIMARS is a highly reliable, combat-proven system that exceeds performance requirements. HIMARS production capacity has already increased from 48 per year to 60 per year and is on track to meet the 96 per year capacity by the end of 2024. To meet this demand, the company has increased its tooling and maximized the space within its factory footprint. Lockheed Martin is also working with its long lead supply chain on increasing production and advancing funds to shorten manufacturing lead time.

Javelin

Javelin’s game-changing capabilities have made a difference on the battlefield for users around the globe. With more than 20 years of proven performance, Javelin is a versatile, shoulder-fired and platform-employed antitank missile system that offers fire-and-forget capability over its full range. While we’ve already increased Javelin production capacity to 2,400 per year, a nearly 15% increase to last year’s production, we’re working with the U.S. Army to eventually increase production capacity to 3,960 Javelins per year by late 2026. This is being accomplished by employing new tooling and test equipment, improving the efficiency of our production line and partnering with our already-active supply chain.

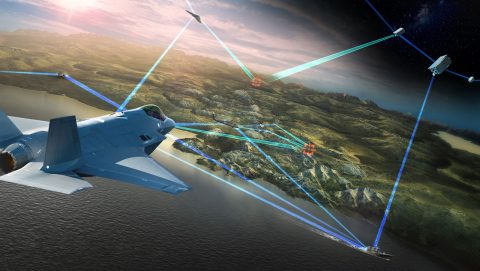

JASSM and LRASM

As one of Lockheed Martin’s first cruise missiles, JASSM has experienced over 20 years of successful partnership with the U.S. Air Force, providing continued significant long-range, precision engagement capabilities in air-to-ground warfare. As a precise, stealthy and survivable cruise missile, LRASM provides multi-service, multi-platform, and multi-mission capabilities for offensive anti-surface warfare. In support of critical weapons capacity for our nation and allies, JASSM/LRASM is positioned to increase production capacity. To demonstrate our commitment to support munitions supply, we opened a 225,000-square-foot advanced manufacturing facility and prepared our supply chain to maximize our mature production line, increase throughput and ensure quality control.

PAC-3

As the world’s most advanced air defense missile, the PAC-3 Missile Segment Enhancement (MSE) defends against emerging advanced threats around the world by using direct body-to-body contact that eliminates targets and keeps critical assets safe. Lockheed Martin has advanced funds to increase PAC-3 MSE annual production rates to 650 by 2027. In 2022, Lockheed Martin opened an 85,000-square-foot building expansion at its Camden, Arkansas facility that supports increased production capacity for PAC-3 MSEs.