The second uncrewed test flight of NASA's Orion, called Exploration Mission-1 (EM-1), is the first time the Orion spacecraft and the Space Launch System (SLS) rocket will undergo an integrated launch beyond the Moon. During launch, the rocket engines and solid rocket boosters ignite creating 8.8 million pounds of thrust, producing deafening sound and vibration that shakes the spacecraft. It's this intense environment that Orion engineers have studied and worked to mitigate when designing the spacecraft. Before Orion flies on EM-1, the limits of the spacecraft’s structures are being taken to the brink in a series of tests at our facility near Denver.

An Orion test structure, called the structural test article (STA), was built and is undergoing punishing tests throughout the year that will deliberately take the vehicle’s structure to the edge of its design. The tests will simulate the raucous launch and harsh space environment throughout the three-week EM-1 mission, that physically affect the structures of the Orion spacecraft. While we test the STA in Denver the “flight” Orion for the EM-1 mission is nearly complete and is being assembled in Florida at the Kennedy Operations and Checkout Building.

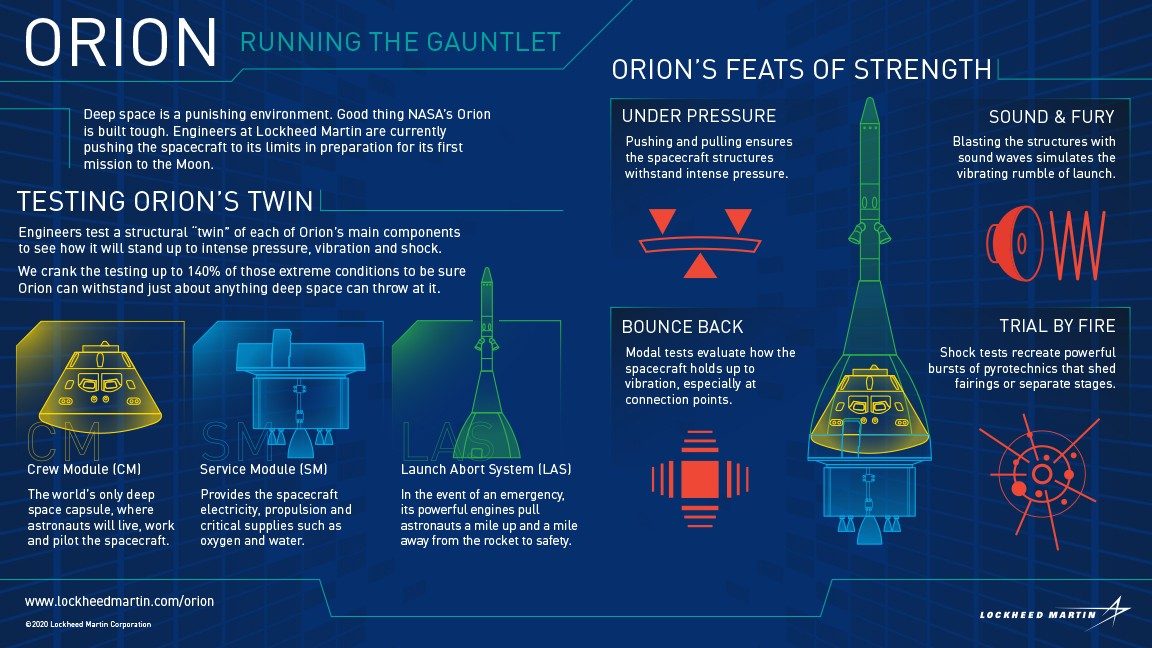

To enable engineers to catch problems on the ground and prevent them from occurring in space, testing on Orion’s structural twin will, in some phases, push expected pressure, vibration and shock conditions up to 40 percent beyond the most severe conditions anticipated during the mission to confirm that the craft can weather any environment it encounters in deep space.

“All of this has to happen before we have a crewed mission,” said Dan Qvale, Orion STA assembly and test lead at Lockheed Martin Space. “Some of the shock events alone that the craft faces are massive and complicated, and we want to validate them here on the ground before the flight Orion, with crew onboard, experiences these dynamic events. After all, it’s all about mission success and the safety of the crew.”

Invaluable to the mission, the tests on Orion’s twin in Colorado provide a way to validate Orion structurally, and enable engineers to push that structure past design standards, without slowing down the progress of the EM-1 flight vehicle’s construction in Florida.

During a typical mission, Orion goes through multiple configurations, so the testing is broken into different states simulating these configurations to mimic the flight configuration and conditions; such as launch, Earth reentry, parachute deployment, etc.

They’re centered on Orion’s three main sections, the crew module, launch abort system (LAS) and service module, which are identical to Orion structurally, but are missing critical non-structural items such as the vehicles computers, propulsion and seats–or its “guts”—not required for these tests.

Dan knows that during these tests, the unexpected awaits, but is confident the Lockheed Martin STA team is can handle any issues they find.

Four Tests, 25 Different Ways

“Running efficient and safe test operations is all about developing a good game plan that takes every contingency into account. We have a team that specializes in doing this and will do whatever it takes. We’re about a third of the way through the test campaign and we’ve already learned a lot.”

What does success look like for this campaign? “Efficiently integrating the test articles into many different configurations, precisely running the tests, and having the test results looking like what we predicted they would.” He adds, “And everyone staying safe, learning and having a good time in the process.”

Once the STA testing campaign is complete, NASA and Lockheed Martin can be confident about the structural integrity of the Orion spacecraft, and Dan says, “NASA can focus on all the cool things they will be able to do with future crewed Orion missions.”

And those are? The Moon, Mars – and beyond.

Meet Dan Qvale: Orion Structural Test Engineer

During a launch, rockets often top speeds of up to 20,000 mph, nearly 10 times faster than the top speed clocked by the record-holding SR-71 Blackbird jet. This pace can generate a few bumps.

Every spacecraft must undergo structural testing to ensure it can withstand the forces, vibrations and noise of a launch.

Q: What is structural testing?

Dan: This test validates the structural design of the spacecraft by physically assessing it against what our design analysis shows it can withstand. We conduct these tests by applying loads to the spacecraft that are 1.4 times what we expect it to encounter during its mission.

Q: Any advice for future testers?

Dan: Test engineering is in many ways similar to a sports team where there is many different positions, but your work supports something or someone down the line. You have to be willing to jump in and get your hands dirty. You do a lot of hands-on work with the spacecraft, so it is exciting work.

Check out more jobs that push our products to the limit.