The phase of maintaining and sustaining military aircraft makes up 70% of the product’s overall service life. It’s the most expensive part of the process, and the decisions made behind sustainment can make or break a program’s performance.

This is no small task.

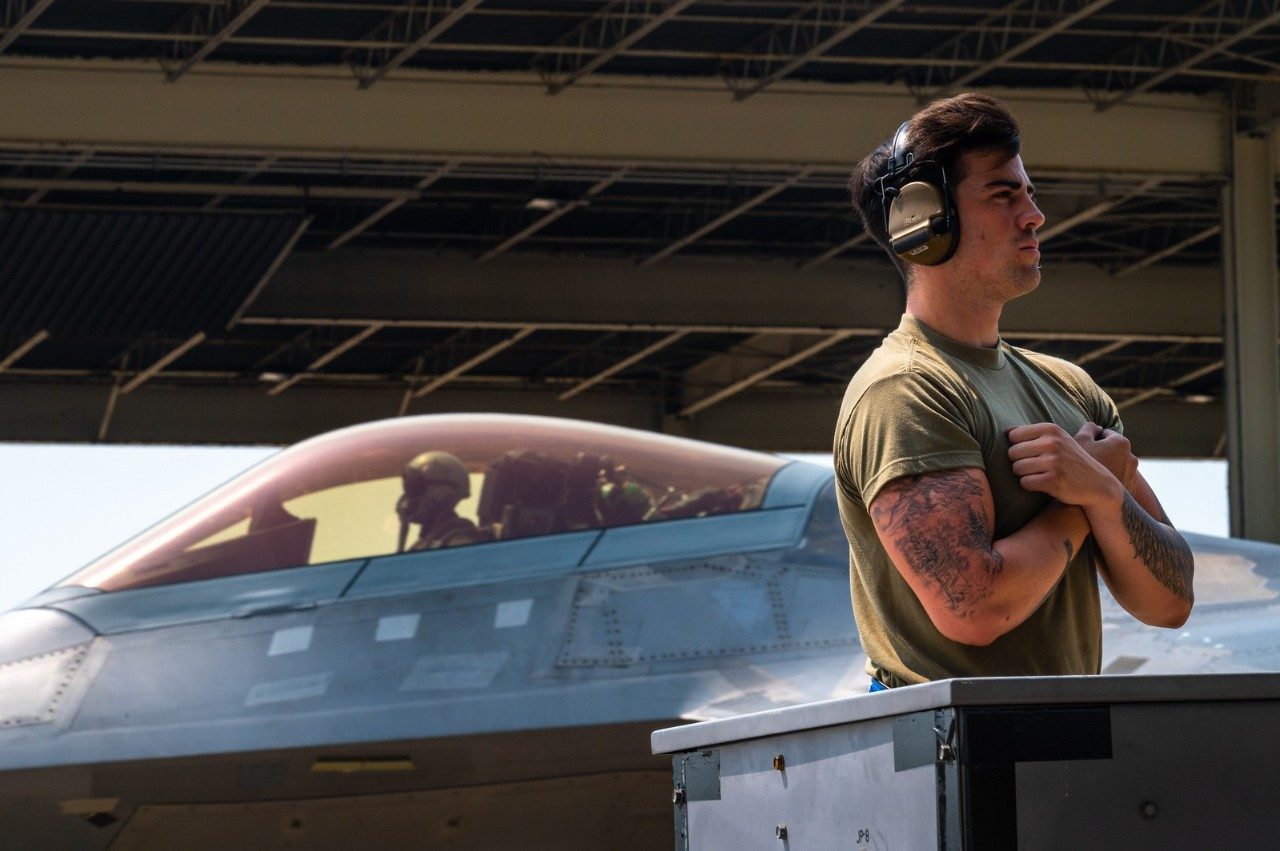

Harnessing the power for digital tools and data mastery is reinventing what good looks like, both for Lockheed Martin and aircraft operators around the globe. As warfare in the 21st century evolves, so must 21st century sustainment. As many facets of our world are finding efficiencies with digital enablement, we’ve turned our digital attention to the flight line.

Here are three ways we’re doing it:

1. Aircraft Inspections Go Unmanned

2. Flight Line Support Gets Interactive

Getting field support at a moment’s notice is required for optimal performance on the flight line. New livestream support tools allow technical experts to connect with operators via mobile video conferencing.

David Rycroft, from the Lockheed Martin Sustainment team shares, “Through remote collaboration, personnel in the field can go beyond basic video conferencing while doing so securely. This tool of the future has already been leveraged at military bases across the globe, and we’re finding additional capabilities through it to meet the mission. This has been a leap in capability to support our customers where and when it matters.”

From the aircraft directly to the expert, these tools can communicate critical mission information without the need for in-person meeting requirements. Virtual circumstances in 2020 prompted the use of this technology, and looking to the future, it will be a standard component of support on the flight line.

3. Virtual Reality, Meet Maintainer Training

New equipment is only as good as the training behind it. By fusing training information, work instructions, and technical data into one streamlined experience, maintainers are now able to practice training in the digital landscape before ever touching a real aircraft.

Mike Toski, Combat Air Modernization Lead shares, “Just like flight simulators for pilots, the future of maintenance training will incorporate a mixture of augmented and virtual reality to prepare maintainers for the flight line. A more prepared maintainer translates to better quality, quicker turn rates and increased system availability. Once implemented, this training transformation can reduce the overall cost of training by 50%.”

Maintainers matter, and these virtually validating training practices give the flight line the necessary backing to launch any mission.