Industry leader in High Volume, Complex, Aircraft Modernization

Lockheed Martin continues to be the global partner of choice for design, manufacturing, systems integration, and engineering solutions that enable military organizations with technical insertions to provide existing fixed and rotary wing aircraft with digital cockpits, weapons systems, mission systems, and defensive systems.

Lockheed Martin is a trusted partner for leading critical aircraft modifications. For two decades, Lockheed Martin successfully managed the high rate, 100% on-time, installation of more than 425 defensive systems on military aircraft, the majority of which were C-130 variants such as the C-130H for the Air National Guard and Air Force Reserve.

Installation Design and Aircraft Modification

Maintaining specialized skills to generate installation designs with a focus on maintaining or enhancing:

• System Performance through wiring design and installation, NVIS compatibility and EMI/EMC conformance

• Mission Performance accounting for cargo space, payload and mission support equipment

• Aircraft Performance comprising of weight management, center-of-gravity and drag

• System Capacity focused on electrical power quality, air conditioning and ECS capability

• Installation Environment concentrated on thermal and vibration management

• Certification to include crash safety, structural and electrical loads, circuit protection and pilot visibility

• Maintenance consisting of operator and maintainer operations, human factors, equipment access, mounting location, and reparability

Solving Complex Challenges in an Evolving Environment

• Demonstrated track record integrating military-unique capabilities on fielded platforms

• Digital Development and Manufacturing Environment (DDME): focused on improving team competencies in model-based engineering, agile development, automation, and industry-leading manufacturing technologies, enabling Lockheed Martin to continue its legacy of delivering affordable, compliant solutions.

• Advancing team competencies: focused on people, tools, facilities, adaptation and metrics ensures support to customer missions into the next generation.

• Specializes in technology insertion of fielded aircraft by bringing retained and modernized subsystems together and ensure they function as a whole.

Lockheed Martin is a leading DoD systems integrator and maintains a broad range of skills to each challenge including systems engineering, software engineering and electrical/mechanical engineering, and specialty engineering (environmental, EMI, HMI, R&M, Safety, and Airworthiness).

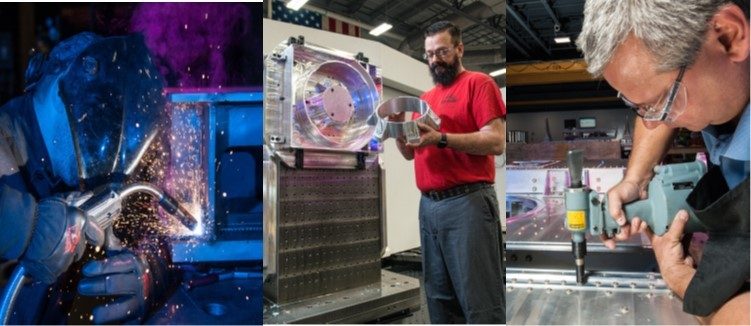

Complementary Manufacturing Capabilities

Aircraft Modernization programs are strategically aligned with the critical production capabilities within Lockheed Martin Rotary and Mission Systems. Through enterprise integration, our geographically dispersed manufacturing capability is set-up as a “single factory” through a common operating system supporting the entire product life-cycle from product fabrication through final integration and test.

Key Manufacturing Centers are focused on continued innovation to ensure that affordable Aircraft Modernization solutions are producible and sustainable, now and in to the future.

• High and Low Complexity Electronics

• Commercial Electronics

• Micro-Electronics

• Complex Metal Fabrication, supported by Hangar Integration facilities

• Advanced Manufacturing Technologies Group

Maintaining core manufacturing capabilities affords Lockheed Martin the ability to support its customers with a range of solutions from complex technology insertions to high-rate aircraft installation.