Mission-Integrated Space Capabilities

Space is the connector. It links our technologies, our security and our humanity. While others view space as a destination, we see it as a place to drive innovation that protects our world, unites every domain and explores the solar system.

As a leader in mission integration, Lockheed Martin accelerates outcomes, delivering on our customer’s most challenging missions. We’re doing this by investing in differentiated capabilities and integrated solutions. We are self-funding technology demonstrations, shouldering risk in service of customer solutions and promoting global collaboration, partnering with companies within and outside of the traditional space sector to drive speed, agility and supply chain resilience.

The space economy is evolving, and the need for human advancements and technological innovation is greater than ever. See how space can connect us, ensuring security and prosperity.

We're Reimagining How Space Can Connect Us

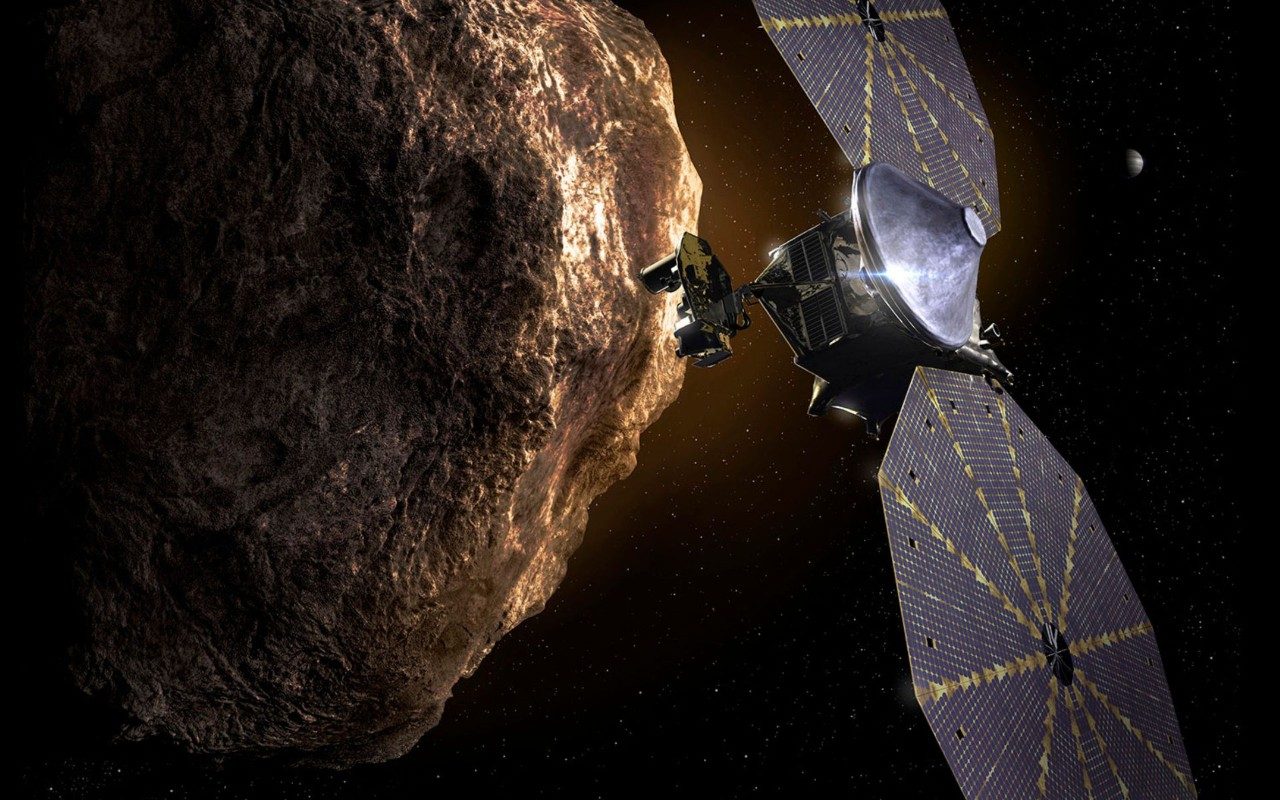

Transforming Space Exploration

We’re advancing spacecraft for Earth observation and scientific discovery. We’re designing, building and testing lunar and deep space exploration capabilities, including NASA’s Orion spacecraft, and creating early-warning weather and climate observation satellites, like the GOES-R series.

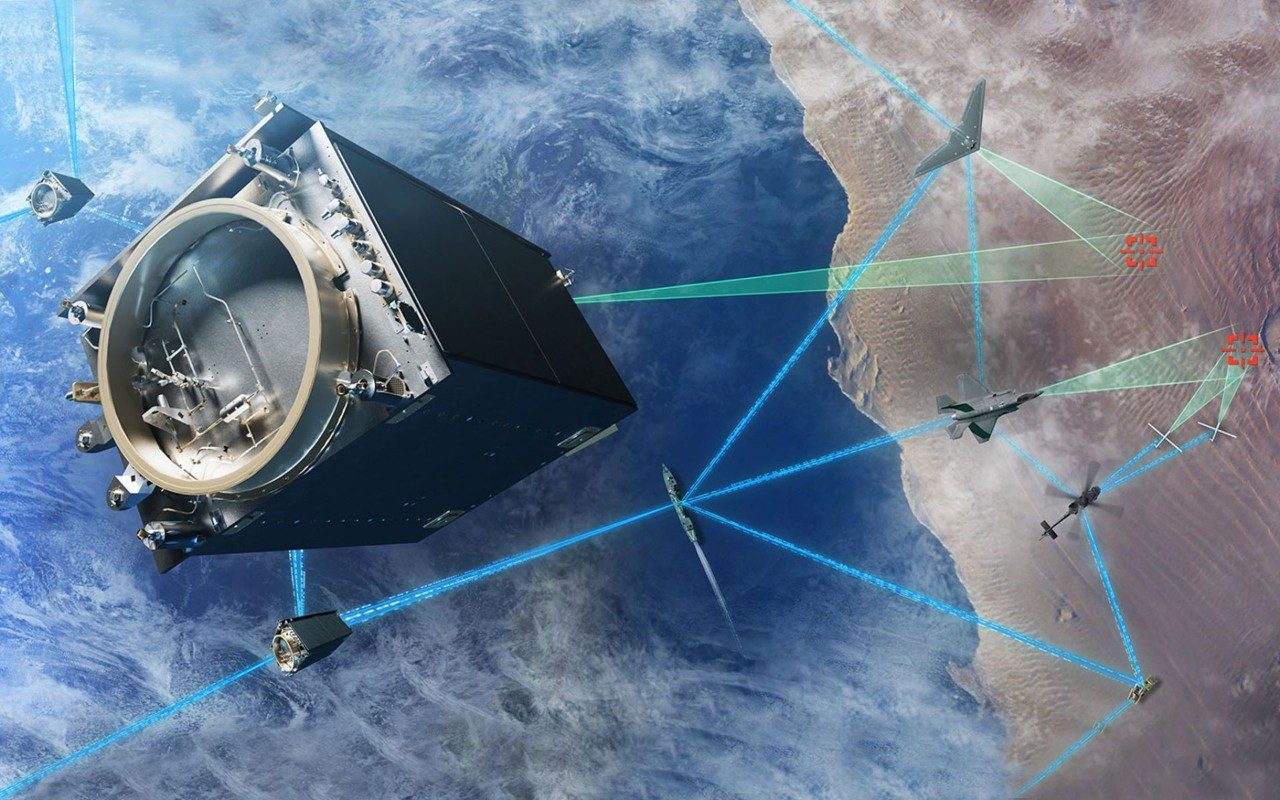

Creating End-To End Mission Solutions

Space is the force multiplier in multi-domain operations. We’re creating breakthrough technologies focusing on resiliency and urgency through our 21st Century Security® vision. We’re integrating platforms, sensors and weapons to provide faster situational awareness and continuous, secured connectivity to share critical mission data between forces in the most contested environments.

Explore Our Space Capabilities and Enabling Technologies

Deep Space Exploration

Human Space Exploration

National Security Space

Strategic & Missile Defense Systems

Weather & Earth Science

A career that's built to inspire.

Embracing the technology of tomorrow is one thing. Anticipating it, envisioning it, building it - that's where we thrive.

Our team creates breakthrough innovations that protect what matters most here on Earth while bringing us closer to discovering more of space.

Explore our skill areas and open roles in space to find your next opportunity.