Lockheed Martin is developing a world-class portfolio of hypersonic technology, designed to protect our nation and deter our adversaries. The company continues building on that leadership with the opening of a new digital factory for hypersonic strike production in Courtland, Alabama.

The 65,000-square-foot Missile Assembly Building 4 (MAB4) is more than a factory. It’s a “digital first” center for the development of hypersonic strike technologies, bringing together the best-of-the-best advanced production technologies from across all of Lockheed Martin.

The MAB4 grand opening on Oct. 4, 2021, represents another milestone in Lockheed Martin’s commitment to establishing northern Alabama as the “Home of Hypersonic Strike Production” and continuing to invest in the state’s economic growth and workforce opportunities.

“Hypersonic weapons play a critical role in deterring our nation’s near-peer threats, and we are proud to partner with our nation’s military for mission success,” said Sarah Hiza, vice president and general manager of the Strategic and Missile Defense Systems at Lockheed Martin Space. “This latest digital factory in Lockheed Martin’s infrastructure means we can make the most of digital engineering practices to revolutionize the way we develop and manufacture American-made hypersonic systems with efficiency and affordability.”

Transformative Focus

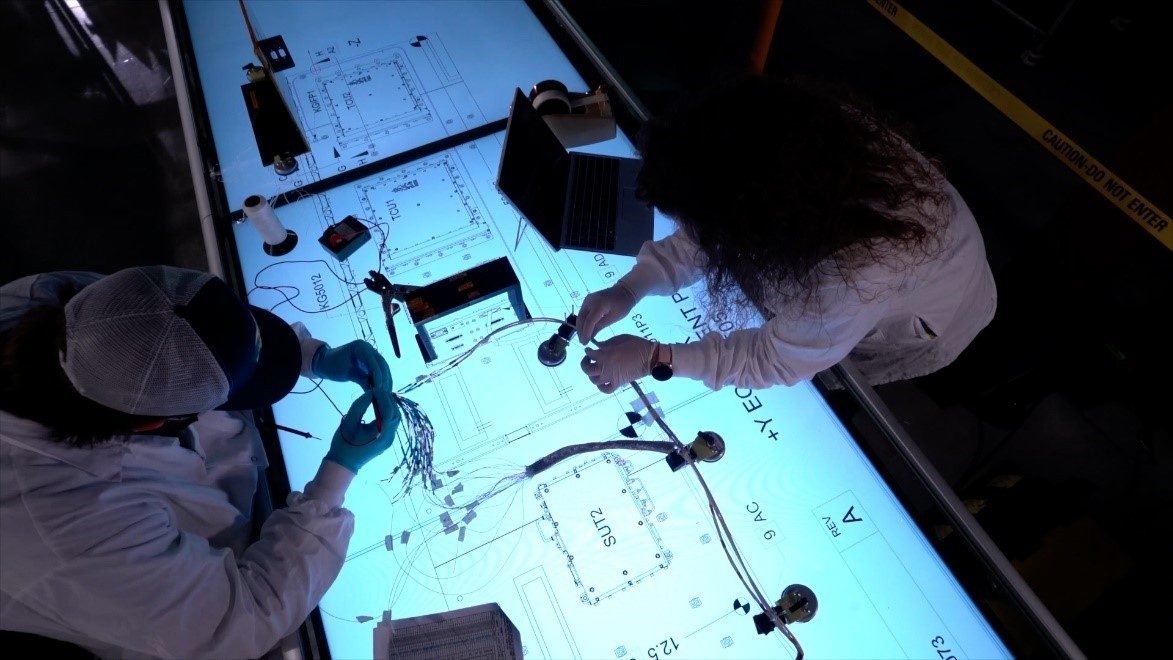

MAB4 is one of several advanced manufacturing centers that Lockheed Martin is opening in the United States in 2021-22. Like its counterparts, MAB4 will incorporate some of our most advanced manufacturing capabilities from across Lockheed Martin including three mission-driven transformation priorities – connection to the Intelligent Factory Framework (IFF), a flexible factory construct to enable production agility and multiple products in the same space, and crucial technology insertions. Digitally linking to the IFF will help enable unprecedented insights into the health, status and optimization of operations.

The skilled team that will be working at MAB4 will leverage cutting-edge technologies, including robotics, electronic foam boards, smart torque tools, artificial intelligence, augmented reality and model-based data consumption on the manufacturing floor feeding the digital thread.

Importance of Hypersonic Capabilities

Digital manufacturing allows the team to carry out production with maximum efficiency. With these advanced capabilities, the team is already delivering on multi-service hypersonic strike programs including Conventional Prompt Strike (CPS), Long Range Hypersonic Weapon (LRHW) and the Air-Launched Rapid Response Weapon (ARRW).

The U.S. government has identified hypersonic strike capabilities as critical for defense against adversaries. The weapons, flying at five times the speed of sound, can intercept and destroy enemy hypersonic missiles.

Researching, designing, developing and producing hypersonic systems requires speed and agility. As a “digital first” factory, MAB4 will deliver that 21st-century warfare technology to the U.S. Army, Air Force and Navy to meet their defense modernization goals at an accelerated pace.

Looking Ahead

This facility continues to strengthen Lockheed Martin’s commitment to making northern Alabama the center of hypersonic strike production. The company’s presence in the area began in 1963 in nearby Huntsville.

Lockheed Martin has been manufacturing defense systems in Courtland since 1994. The company began construction on nine buildings on the 660-acre campus, the former site of a World War II-era U.S. Army Air Corps base.

Over the past two years, the Courtland facility has added a total of 117,000 square feet of manufacturing space. With this growth, the team will bring approximately 70 jobs to Courtland and another 200 jobs to Huntsville, headquarters for hypersonic program management and engineering functions. Lockheed Martin currently employs approximately 2,600 people in Alabama.

Economic Growth and Workforce Development

Continuing to train a skilled workforce for its growing programs is a priority for Lockheed Martin and its state, academic and military partners. One of the key examples of this commitment is the Advanced Manufacturing Technician Apprenticeship Program (AMTAP), which has had 40 graduates of the program join the Courtland team full-time. With every dollar invested in this training program, turns into $6.62 back in the Alabama economy.

To continue strengthen critical manufacturing skills and provide learning opportunities for the region’s local workforce, Lockheed Martin has also partnered with Aerospace States Association and Calhoun Community College. These partnerships are creating new internship programs, educational opportunities, and focusing on strengthening small businesses.

Do you want to be part of creating the next generation of defense for our nation? Find out how you can join our team here.

MAB4 By the Numbers

- Ground broken in September 2020

- 65,000 square feet of manufacturing and office space

- Located on a 660-acre campus, former site of a World War II-era U.S. Army Air Corps base

- Approximately 70 new jobs in Courtland

Lockheed Martin’s Digital Factories

- STAR (Spacecraft, Test, Assembly and Resource) Center in Titusville, Florida.

- Skunk Works® aerospace facility in Palmdale, California.

- MAB4 (Missile Assembly Building 4) in Courtland, Alabama.