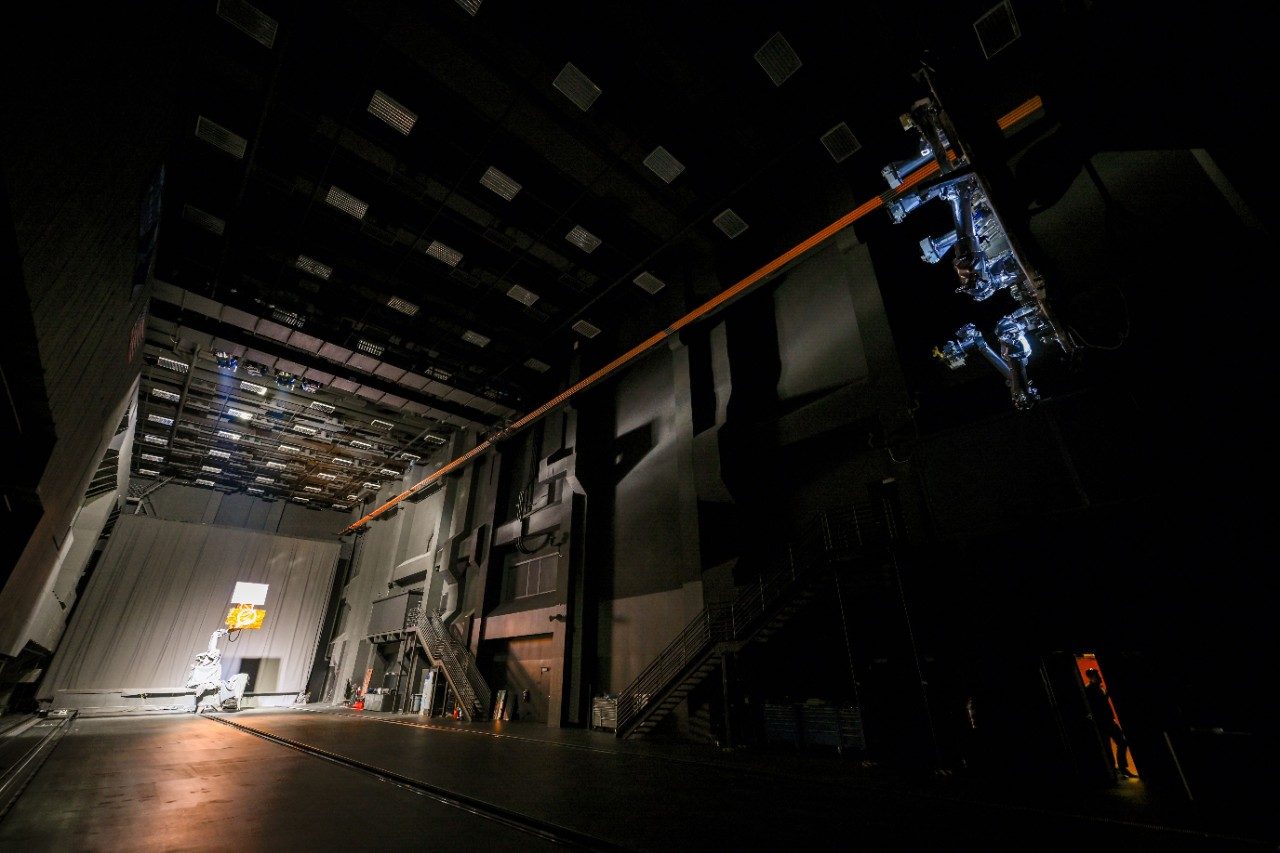

A World-Class RPOD Testing Facility

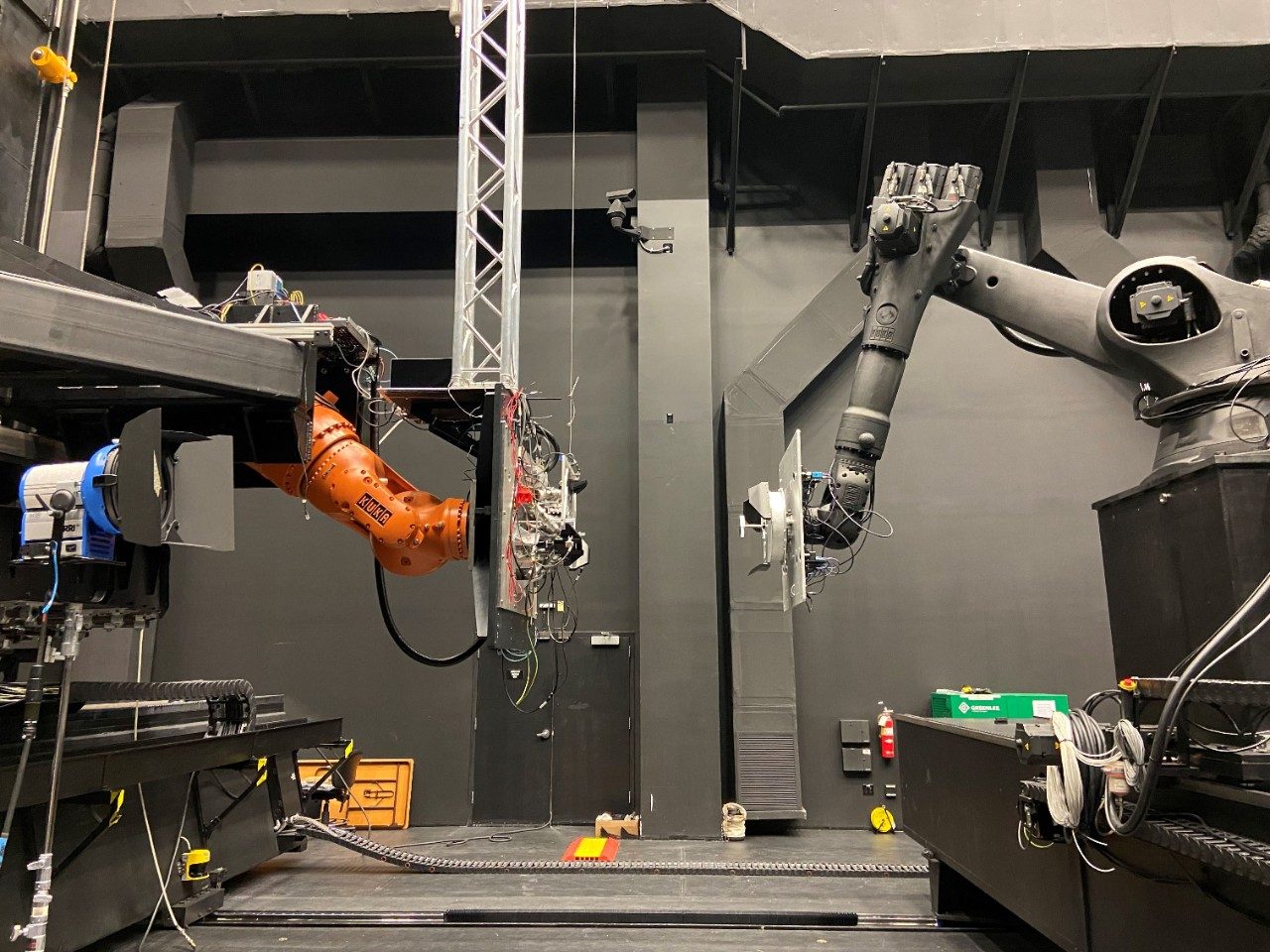

The Space Operations Simulation Center (SOSC) is the largest spacecraft test facility of its kind. It simulates on-orbit conditions for rendezvous, proximity operations and docking (RPOD) missions.

The SOSC supports mission-critical, high-risk testing for close-range maneuvers such as approach, interaction and connection of crewed and uncrewed spacecraft. It can help identify and fix issues early, reducing the risk of costly rework or even mission failure.

Unmatched Capabilities

What sets our facility apart is a unique combination of size, capability and expertise from a name you know and can trust.

The Largest RPOD Test Facility

Weight Capacity

Highly Precise and Accurate

Unparalleled Expertise

See how this one-of-a-kind facility provides a high-fidelity environment for RPOD testing of critical spacecraft missions.

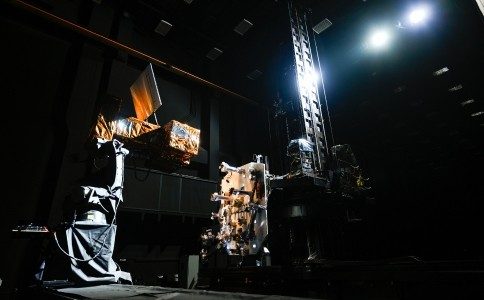

Comprehensive RPOD Testing Services

Our state-of-art facility can help detect issues early, saving time and reducing risk. Our RPOD testing includes:

- verification of guidance, navigation, and control (GN&C) systems, with the ability to characterize, test, and validate the many components at a unit or systems level;

- simulation of space lighting conditions, like shadows, mockup infrared (IR), and full solar intensity lighting;

- mechanical contact testing with both small and large mass configurations;

- testing scenarios using six-degrees of freedom (6DOF) robots enabling precise simulation of on-orbit trajectories;

- and live augmented reality (AR) demonstrations for tracking mockup movements and visually demonstrating deliverables.

Specialty Lighting Solutions

Our unique solar simulations, including IR camera and lighting detection along with ranging (LiDAR) Lambertian targets, provide the most accurate mock environment to test changes in lighting conditions. It also ensures sensor performance during pre-launch, and its ability to withstand the extreme space environment.

Integrated Systems Testing

With a ‘test like you fly’ philosophy, the SOSC provides an environment designed to proactively detect anomalies with integrated, mission-focused testing.

Systems-level testing – Our approach helps ensure spacecraft functionality within larger systems. This leads to better overall performance, and reduces late-breaking findings that can cause significant cost and schedule impacts.

Rapid development – Our systems accelerate the development of new GN&C systems. Early characterization, image collection, and sensor testing, raises awareness of potential issues. These findings enable early course correction, support design maturation and help deliver mission success.

Specialty Services

Take a concept to a functional prototype in two business days. Our unique specialty services deliver fast, efficient modeling and prototyping with distinct benefits:

- access to unrestricted parts libraries

- decades of experience across dozens of prototype, EDU, flight, and on-orbit designs

- minimal documentation requirements

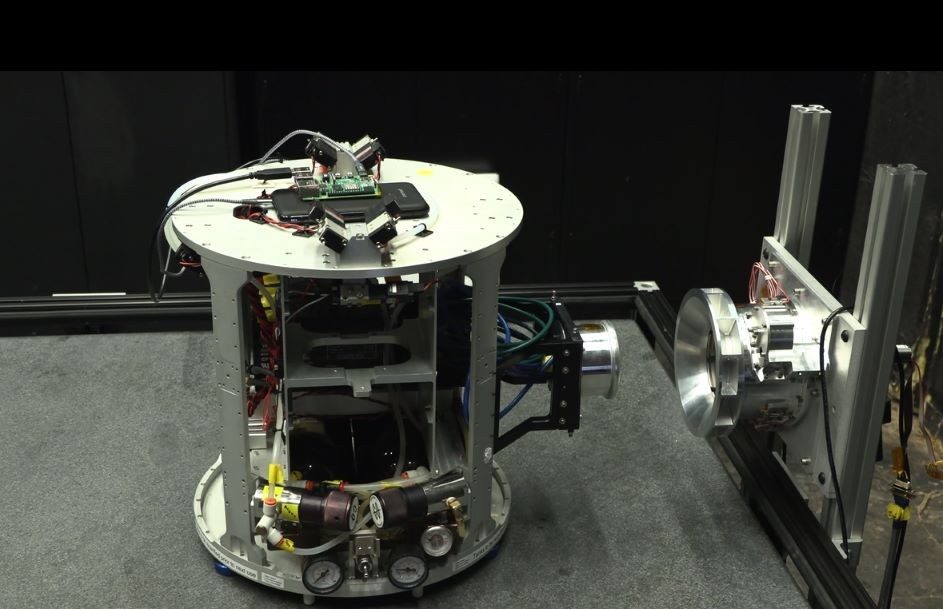

Machining and modeling – We have the capability to rapidly create small to life-size mockups to enable testing of any spacecraft design. Our on-site machine shop enables custom design and fabrication of flight boxes, enclosures, industrial cabinetry, air bearing robots, complex designs and more.

Electronics and board prototyping capability – We can test and detect electronic issues through our prototyping capabilities. We can develop full cycle circuit-to-CCA designs like payload controllers, motor drivers, power supplies, camera, sensors, interfaces and more.