F-35 Supplier Spotlight: Specialized Actuation Manufacturing at Vaughan, Ontario’s Ben Machine

Behind the F-35’s advanced capabilities is a global supply chain delivering highly specialized technologies that support the aircraft throughout its lifecycle. As the program grows across allied nations, Canadian suppliers are playing a critical role in providing the systems and expertise that help keep the global F-35 fleet mission-ready.

For more than two decades, Vaughan-based Ben Machine has been a part of that effort, contributing to the development and manufacturing of the F-35’s actuation system through its specialized dip brazing expertise.

The actuation system is a critical component of the aircraft, responsible for controlling the movements that allow the world’s most advanced fighter jet to maneuver in flight, acting like the muscles of the aircraft.

Building Specialized Capability in Canada

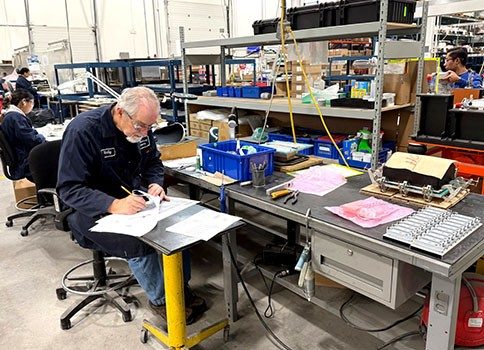

Founded in 1973, Ben Machine has built a long-standing presence within Canada’s defence industrial base, supporting a wide range of aerospace and defence initiatives for both Canadian and international customers. Over time, the company has developed a highly specialized capability that sets it apart within the aviation defence industry. Today, Ben Machine is the only company in North America able to deliver the actuation system to the required specifications for the F-35.

This important role within the F-35 supply chain has driven significant growth for the company. Since joining the program, Ben Machine has seen its workforce grow by more than 350 per cent and now employs 220 Canadians across a wide range of skill sets.

“The F-35 program has provided our company with stability in production demand and the opportunity to develop new capabilities to support a truly cutting-edge platform,” says Michael Iacovelli, CEO, Ben Machine. “It has also brought a level of prestige and proven capability that helps us secure new opportunities in the defence space and, importantly, allows us to give back to the community.”

Impact that Extends Beyond Production

The benefits of the F-35 program extend beyond high-quality jobs. Participation in the project has also enabled Ben Machine to build collaborative relationships with local colleges and universities across Ontario, helping to strengthen the future workforce of Canada’s aerospace and defence sector.

The scale and longevity of the F-35 program set it apart from traditional defence projects. As the aircraft continues to be produced and sustained worldwide, Canadian suppliers like Ben Machine are positioned to maintain and build lasting roles within the program, translating advanced manufacturing expertise into long-lasting employment and economic impact at home.